GASO T140 (133T-4) Triplex Plunger Pump Get a Quote!

IEQ is an OEM supplier of the GASO T140 Pump. Let the friendly customer service staff at IEQ Industries help you find the GASO Pump you need.

Download this data in PDF form.

Specifications

Pump Size:

maximum plunger size x stroke length, in.(mm)

3.375 x 4.500 (85.7 x 114.3)

Rated BPH:(kW) at 400 RPM (Crankshaft speed)

133 (99)

Rated plunger load: pounds (kg)

8800 (3992)

Maximum discharge pressure: psi (kPa)

"L" model: 1440 (9929)

"M" model: 3600 (24821)

"H" model: 6000 (41369)

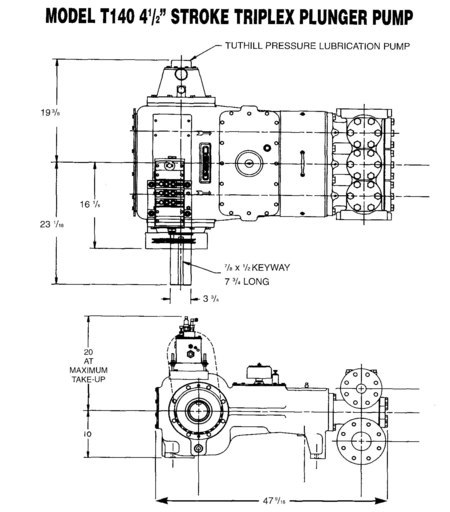

Crankshaft extension:

Diameter, in.(mm): 3.750 (95.25)

Length, in.(mm): 9.84 (249.9)

Keyway width x depth, in.(mm):

7/8 x 1/2 (22.225 x 12.7)

Maximum recommended sheave diameter, in.(mm):

53 (1346.2)

For larger sizes: Contact IEQ

Pinion shaft extension:

if gear reducer is supplied, in.(mm)

For belt or chain drive: Contact Factory

For direct drive: Diameter, in.(mm): 2.000 (50.8)

Length, in.(mm): 4.25 (108.0)

Keyway width x depth, in.(mm):

1/2 x 1/4 (12.70 x 6.35)

Accessory gear reduction unit:

3.00:1, 3.12:1, 3.23:1, 3.36:1, 3.49:1

3.62:1, 3.78:1, 3.94:1, 4.11:1, 4.29:1,

4.48:1, 4.69:1, 4.93:1, 5.17:1

Oil Capacity: gallons (L)

Crankcase: 2.50 (9.46)

Gear Reducer varies with ratio:

1.25 to 1.50 (4.73 to 5.68)

Weight: pump only on wood shipping skids, pounds (kg)

"L" model: 1650 (748)

"M" model: 1650 (748)

"H" model: 1650 (748)

Standard Materials for Fluid Ends:

"L" model

Cast Duplex Stainless Steel

Cast Nickel Aluminum Bronze

Forged/Plate Carbon Steel

"M" model

Cast Duplex Stainless Steel

Cast Nickel Aluminum Bronze

Forged/Plate Carbon Steel

"H" model

Forged Carbon Steel

Duplex Stainless Steel

| Pump Model | Flange Connections | Dimensions (Inches) | ||||||

| Discharge Connection Sizes | Suction Connection Sizes | A | B | C | D | E | F | |

| 133T-4L | 3 (76.2)-ANSI 600 FF | 6 (152.4)-ANSI 150 FF | 4 5/8 | 7 7/8 | 21 | 33 3/4 | 48 5/8 | 9 5/8 |

| 133T-4M | 2 (50.8)-ANSI 1500 FF | 4 (101.6)-ANSI 300 FF | 5 1/16 | 6 3/16 | 21 | 33 3/8 | 47 3/4 | 9 |

| 133T-4H | 2 (50.8)-ANSI 2500 RJ | 3 (76.2)-ANSI 2500 RJ | 5 1/8 | 6 1/8 | 30 1/8 | 36 3/4 | 52 1/2 | 12 1/8 |

Performance Data

| PUMP | English Units | 100 RPM | 150 RPM | 250 RPM | 300 RPM | 350 RPM | 400 RPM | ||||||||||

| Plunger Dia. In. | Plunger Area Sq. In. | BPD per RPM | GPM per RPM | Max. Press. PSI | BPD | GPM | BPD | GPM | BPD | GPM | BPD | GPM | BPD | GPM | BPD | GPM | |

| 133T-4L (T140-4) | 3.375 | 8.9462 | 17.9255 | 0.5228 | 984 | 1793 | 52.3 | 2689 | 78.4 | 4482 | 130.7 | 5378 | 156.8 | 6274 | 183.0 | 7171 | 209.1 |

| 3.250 | 8.2958 | 16.6223 | 0.4848 | 1061 | 1663 | 48.5 | 2494 | 72.7 | 4156 | 121.2 | 4987 | 145.4 | 5818 | 169.7 | 6649 | 193.9 | |

| 3.125 | 7.6699 | 15.3682 | 0.4482 | 1147 | 1537 | 44.8 | 2306 | 67.2 | 3843 | 112.1 | 4611 | 134.5 | 5379 | 156.9 | 6148 | 179.3 | |

| 3.000 | 7.0686 | 14.1634 | 0.4131 | 1245 | 1417 | 41.3 | 2125 | 62.0 | 3541 | 103.3 | 4250 | 123.9 | 4958 | 144.6 | 5666 | 165.2 | |

| 2.875 | 6.4918 | 13.0077 | 0.3794 | 1356 | 1301 | 37.9 | 1952 | 56.9 | 3252 | 94.8 | 3903 | 113.8 | 4553 | 132.8 | 5204 | 151.8 | |

| 2.750 | 5.9396 | 11.9012 | 0.3471 | 1440 | 1191 | 34.7 | 1786 | 52.1 | 2976 | 86.8 | 3571 | 104.1 | 4166 | 121.5 | 4761 | 138.8 | |

| 2.625 | 5.4119 | 10.8438 | 0.3163 | 1440 | 1085 | 31.6 | 1627 | 47.4 | 2711 | 79.1 | 3254 | 94.9 | 3796 | 110.7 | 4338 | 126.5 | |

| 133T-4M (T140-3) | 2.500 | 4.9087 | 9.8357 | 0.2869 | 1793 | 984 | 28.7 | 1476 | 43.0 | 2459 | 71.7 | 2951 | 86.1 | 3443 | 100.4 | 3935 | 114.7 |

| 2.375 | 4.4301 | 8.8767 | 0.2589 | 1986 | 888 | 25.9 | 1332 | 38.8 | 2220 | 64.7 | 2664 | 77.7 | 3107 | 90.6 | 3551 | 103.6 | |

| 2.250 | 3.9761 | 7.9669 | 0.2324 | 2213 | 797 | 23.2 | 1196 | 34.9 | 1992 | 58.1 | 2391 | 69.7 | 2789 | 81.3 | 3187 | 92.9 | |

| 2.125 | 3.5466 | 7.1063 | 0.2073 | 2481 | 711 | 20.7 | 1066 | 31.1 | 1777 | 51.8 | 2132 | 62.2 | 2488 | 72.5 | 2843 | 82.9 | |

| 2.000 | 3.1416 | 6.2948 | 0.1836 | 2801 | 630 | 18.4 | 945 | 27.5 | 1574 | 45.9 | 1889 | 55.1 | 2204 | 64.3 | 2518 | 73.4 | |

| 1.875 | 2.7612 | 5.5326 | 0.1614 | 3187 | 554 | 16.1 | 830 | 24.2 | 1384 | 40.3 | 1660 | 48.4 | 1937 | 56.5 | 2214 | 64.5 | |

| 1.750 | 2.4053 | 4.8195 | 0.1406 | 3600 | 482 | 14.1 | 723 | 21.1 | 1205 | 35.1 | 1446 | 42.2 | 1687 | 49.2 | 1928 | 56.2 | |

| 101T-4H (T100-2) | 1.625 | 2.0739 | 4.1556 | 0.1212 | 4243 | 416 | 12.1 | 624 | 18.2 | 1039 | 30.3 | 1247 | 36.4 | 1455 | 42.4 | 1663 | 48.5 |

| 1.500 | 1.7671 | 3.5408 | 0.1033 | 4980 | 355 | 10.3 | 532 | 15.5 | 886 | 25.8 | 1063 | 31.0 | 1240 | 36.1 | 1417 | 41.3 | |

| 1.375 | 1.4849 | 2.9753 | 0.0868 | 5926 | 298 | 8.7 | 447 | 13.0 | 744 | 21.7 | 893 | 26.0 | 1042 | 30.4 | 1191 | 34.7 | |

| 1.250 | 1.2272 | 2.4589 | 0.0717 | 6000 | 246 | 7.2 | 369 | 10.8 | 615 | 17.9 | 738 | 21.5 | 861 | 25.1 | 984 | 28.7 | |

| Brake Horsepower required | 34 | 51 | 84 | 100 | 117 | 133 | |||||||||||

| PUMP | Metric Units | 100 RPM | 150 RPM | 250 RPM | 300 RPM | 350 RPM | 400 RPM | ||||||||||

| Plunger Dia. mm | Plunger Area cm2 | M3/Hr per RPM | L/Sec. per RPM | Max. Press. kPa | M3/Hr | L/Sec. | M3/Hr | L/Sec. | M3/Hr | L/Sec. | M3/Hr | L/Sec. | M3/Hr | L/Sec. | M3/Hr | L/Sec. | |

| 133T-4L (T140-4) | 86 | 57.717 | 0.1187 | 0.0330 | 6782 | 11.9 | 3.3 | 17.8 | 4.9 | 29.7 | 8.2 | 35.6 | 9.9 | 41.6 | 11.5 | 47.5 | 13.2 |

| 83 | 53.521 | 0.1101 | 0.0306 | 7314 | 11.0 | 3.1 | 16.5 | 4.6 | 27.5 | 7.6 | 33.0 | 9.2 | 38.5 | 10.7 | 44.0 | 12.2 | |

| 79 | 49.483 | 0.1018 | 0.0283 | 7911 | 10.2 | 2.8 | 15.3 | 4.2 | 25.4 | 7.1 | 30.5 | 8.5 | 35.6 | 9.9 | 40.7 | 11.3 | |

| 76 | 45.604 | 0.0938 | 0.0261 | 8584 | 9.4 | 2.6 | 14.1 | 3.9 | 23.5 | 6.5 | 28.1 | 7.8 | 32.8 | 9.1 | 37.5 | 10.4 | |

| 73 | 41.883 | 0.0862 | 0.0239 | 9346 | 8.6 | 2.4 | 12.9 | 3.6 | 21.5 | 6.0 | 25.8 | 7.2 | 30.2 | 8.4 | 34.5 | 9.6 | |

| 70 | 38.320 | 0.0788 | 0.0219 | 9929 | 7.9 | 2.2 | 11.8 | 3.3 | 19.7 | 5.5 | 23.6 | 6.6 | 27.6 | 7.7 | 31.5 | 8.8 | |

| 67 | 34.915 | 0.0718 | 0.0200 | 9929 | 7.2 | 2.0 | 10.8 | 3.0 | 18.0 | 5.0 | 21.5 | 6.0 | 25.1 | 7.0 | 28.7 | 8.0 | |

| 133T-4M (T140-3) | 64 | 31.669 | 0.0651 | 0.0181 | 12360 | 6.5 | 1.8 | 9.8 | 2.7 | 16.3 | 4.5 | 19.5 | 5.4 | 22.8 | 6.3 | 26.1 | 7.2 |

| 60 | 28.581 | 0.0588 | 0.0163 | 13696 | 5.9 | 1.6 | 8.8 | 2.5 | 14.7 | 4.1 | 17.6 | 4.9 | 20.6 | 5.7 | 23.5 | 6.5 | |

| 57 | 25.652 | 0.0528 | 0.0147 | 15260 | 5.3 | 1.5 | 7.9 | 2.2 | 13.2 | 3.7 | 15.8 | 4.4 | 18.5 | 5.1 | 21.1 | 5.9 | |

| 54 | 22.881 | 0.0471 | 0.0131 | 17108 | 4.7 | 1.3 | 7.1 | 2.0 | 11.8 | 3.3 | 14.1 | 3.9 | 16.5 | 4.6 | 18.8 | 5.2 | |

| 51 | 20.268 | 0.0417 | 0.0116 | 19313 | 4.2 | 1.2 | 6.3 | 1.7 | 10.4 | 2.9 | 12.5 | 3.5 | 14.6 | 4.1 | 16.7 | 4.6 | |

| 48 | 17.814 | 0.0366 | 0.0102 | 21974 | 3.7 | 1.0 | 5.5 | 1.5 | 9.2 | 2.5 | 11.0 | 3.1 | 12.8 | 3.6 | 14.7 | 4.1 | |

| 44 | 15.518 | 0.0319 | 0.0089 | 24821 | 3.2 | 0.9 | 4.8 | 1.3 | 8.0 | 2.2 | 9.6 | 2.7 | 11.2 | 3.1 | 12.8 | 3.5 | |

| 133T-4H (T140-2) | 41 | 13.380 | 0.0275 | 0.0076 | 29256 | 2.8 | 0.8 | 4.1 | 1.1 | 6.9 | 1.9 | 8.3 | 2.3 | 9.6 | 2.7 | 11.0 | 3.1 |

| 38 | 11.401 | 0.0235 | 0.0065 | 34335 | 2.3 | 0.7 | 3.5 | 1.0 | 5.9 | 1.6 | 7.0 | 2.0 | 8.2 | 2.3 | 9.4 | 2.6 | |

| 35 | 9.580 | 0.0197 | 0.0055 | 40861 | 2.0 | 0.5 | 3.0 | 0.8 | 4.9 | 1.4 | 5.9 | 1.6 | 6.9 | 1.9 | 7.9 | 2.2 | |

| 32 | 7.917 | 0.0163 | 0.0045 | 41369 | 1.6 | 0.5 | 2.4 | 0.7 | 4.1 | 1.1 | 4.9 | 1.4 | 5.7 | 1.6 | 6.5 | 1.8 | |

| Kilowatts required | 25 | 38 | 63 | 75 | 87 | 99 | |||||||||||

For operation below 150 RPM, an auxiliary lubrication system is required.

Volumetric Rate is based on 100% Volumetric Efficiency. Brake Horsepower/Kilowatts Required is based on 90% Mechanical Efficiency.