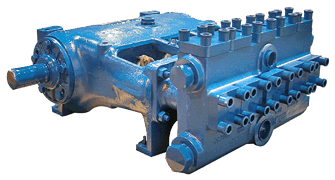

Specifications for duplex piston pump parts

Power Frame

One-piece, close grain, cast iron casting with heavy wall sections, well ribbed to insure rigid construction and designed to fully enclose all working parts.

Gears

Herringbone construction. Main gear is heat treated high grade ductile iron. Pinion gear is cut from forged alloy steel and hardened.

Crankshaft

Heavy center section for mounting main gear. Large diameter crank pins for optimum load capacity.

Pinion Shaft

Machined and precision ground from heat treated alloy carbon steel.

Bearings

Heavy duty tapered roller bearings do crankshaft. Self- contained double row ball bearings or single row straight roller bearings on pinion shaft to permit free floating of shaft for self-centering of gears.

Connecting Rods

Heavy cross section castings with renewable babbitt lined steel shell bearings in crank end; bronze bushings in crosshead end.

Crossheads

Cylindrical-type, one-piece, cast iron castings. Crosshead pins are case hardened and precision ground steel.

Lubrication

All power end parts, crank and pinion shafts including gears, crossheads, connecting rod bearings, crankshaft bearings, and pinion shaft bearings are lubricated by a field proven crankcase reservoir splash-gravity feed system

Stuffing Boxes

All duplex pumps are furnished with replaceable type cast iron stuffing boxes.

Packing

Standard packing is a set of lip-type or square packing rings depending upon the application.

LIQUID END SPECIFICATIONS:

Liquid End Body

Standard materials available are ductile iron and steel castings. Liquid ends can be trimmed out for pumping various liquids.

Cylinder Heads

Heavy section steel bolt-on type with O-ring gaskets.

Valve Covers

Heavy section steel bolt-on type with O-ring gaskets.

Liners

All pumps are available with interchangeable type liners. Standard materials include cast iron, file hard steel and special corrosion resistant liners.

Piston Rods

Various materials are available for straight or API taper rods. Some of these are; steel, stainless steel, file hard steel, and chrome plated steel.

Pistons

Cast iron bodies fitted with various types of rings are available. Slush service pistons can also be furnished.

Valves

Valves and seats are available as follows; Hardened and ground steel wing guided and bronze wing guided. Stainless steel disc valves with stainless steel seats. Various styles of slush type valves are also available.

Stuffing Boxes

All duplex pumps are furnished with replaceable type boxes which are available in cast iron, steel and nickel aluminum bronze.

Packing

Standard packing is a set of lip-type or square packing rings. Other packings can be furnished for special applications.

Stuffing Box Lubrication

Optional, depending on the application. Furnished by use of a regulated flow of oil from a force feed lubricator mounted on the pump, with a separate oil line to each stuffing box and V-belt driven.

Duplex, Triplex and Quintuplex Plunger Pump Specifications POWER END SPECIFICATIONS:

Power Frame

Meehanite GD-35 gray iron casting with heavy wall sections, well ribbed to insure rigid construction.

Internal Gear Reducer

T450 furnished with standard integral gear reducer.

Crankshaft

Mounted with center line of shaft on center line of crossheads. Machined for mounting shaft extension on off-drive side. Crankshaft may extend from either side except on models 5350 and 5698 which are left hand drive only.

Crankshaft Bearings

Interchangeable heavy duty tapered roller bearings, straight roller or spherical roller bearings, depending upon the pump model.

Connecting Rods

T450, T200 and Q350 rods are cast with a lubricated hole through the center of the rod. All models except the T450 have bronze bushings at the crosshead end. T450 is standard with the needle bearing design. An optional needle bearing design in lieu of a bronze bushing is available. These models along with all 3300, 2900 and 2800 models have precision bearings at the crank end. Other plunger pumps are equipped with "H" type connecting rods, with renewable babbitt lined steel backed shell bearings at the crank end and bronze bushings at the crosshead end.

Crossheads

Cylindrical-type Meehanite GD-35 gray iron castings, except for models 3500, T450 and 3900 which are semi-cylindrical type ductile iron castings. Crosshead pins are hardened and ground steel.

LUBRICATION

Power end parts are lubricated by splash system from oil in crankcase reservoir. Power frame has an oil return channel, from front of crossheads back to crankcase to permit constant circulation of oil and to help keep oil cool. Positive power end lubrication is standard on models T200, Q350 and T450 pumps.

Stuffing Boxes

Power end parts are lubricated by splash system from oil in crankcase reservoir. Power frame has an oil return channel, from front of crossheads back to crankcase to permit constant circulation of oil and to help keep oil cool. Positive power end lubrication is standard on models T200, Q350 and T450 pumps. All models are furnished with nonadjustable lip-type packing rings.

LIQUID END SPECIFICATIONS:

Liquid End Body

Standard materials available from stock are ductile iron for crude oil and fresh water service, steel for pumping petroleum products in hazardous locations, and nickel aluminum bronze alloys for saltwater and other corrosive liquids. Special alloys such as Hastelloy C, Carpenter #20, Inconel or Stainless Steel can be furnished upon request.

Valves

A variety of valve designs and materials are available dependent upon service conditions.

Materials available are: Hard surfaced or ceramic coated stainless steel, solid ceramic, or other materials or surfacing required by the application.

Stuffing Boxes

Stuffing boxes are either bored directly into the liquid body or are of the replaceable type.

Packing

Standard packing is a set of non-adjustable lip type packing rings. Other packing can be furnished for special applications.

Plunger Lubrication

Optional, depending on the application. Furnished by use of drip oilers or a regulated flow of oil from a force-feed lubricator. Lubricator is V-belt driven and mounted on the pump with separate oil lines to stuffing box